Revolutionizing Denture Repairs with 3D Printing

In the ever-evolving world of dentistry, 3D printing is taking center stage as a transformative technology. For patients and dental professionals alike, the application of 3D printing in denture repairs is a game-changer. It combines speed, precision, and cost-efficiency to deliver unparalleled results. Let’s explore how 3D printing is revolutionizing denture repairs and why it’s a superior choice.

Why Choose 3D-Printed Dentures?

Traditional dentures have served patients well for decades, but they come with limitations. The process of creating and repairing traditional dentures can be lengthy, costly, and prone to inaccuracies. 3D-printed dentures, on the other hand, offer a modern solution that addresses these challenges head-on.

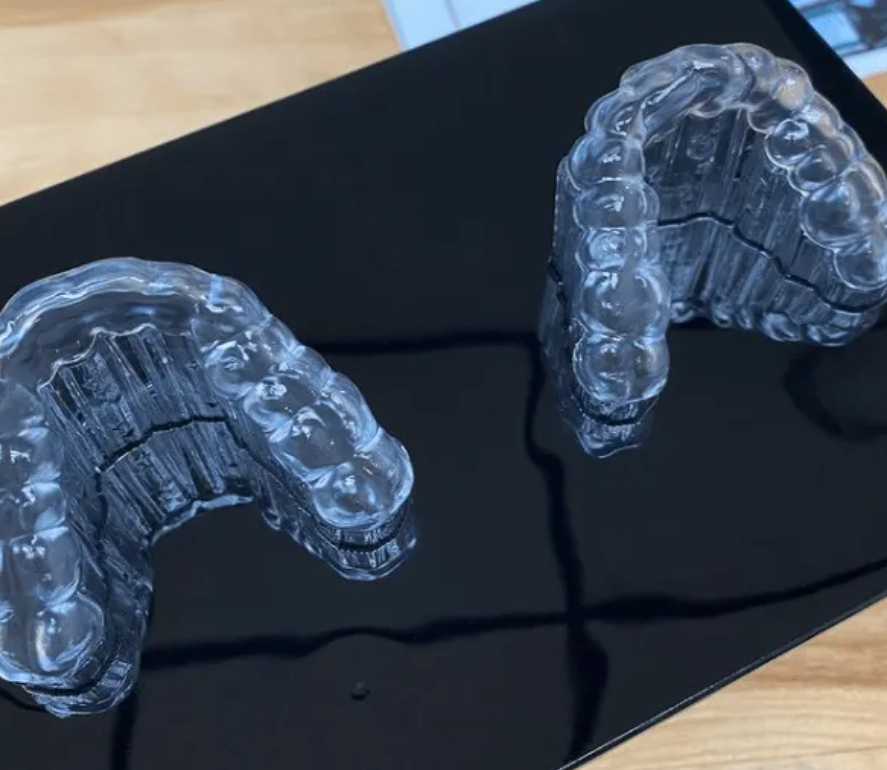

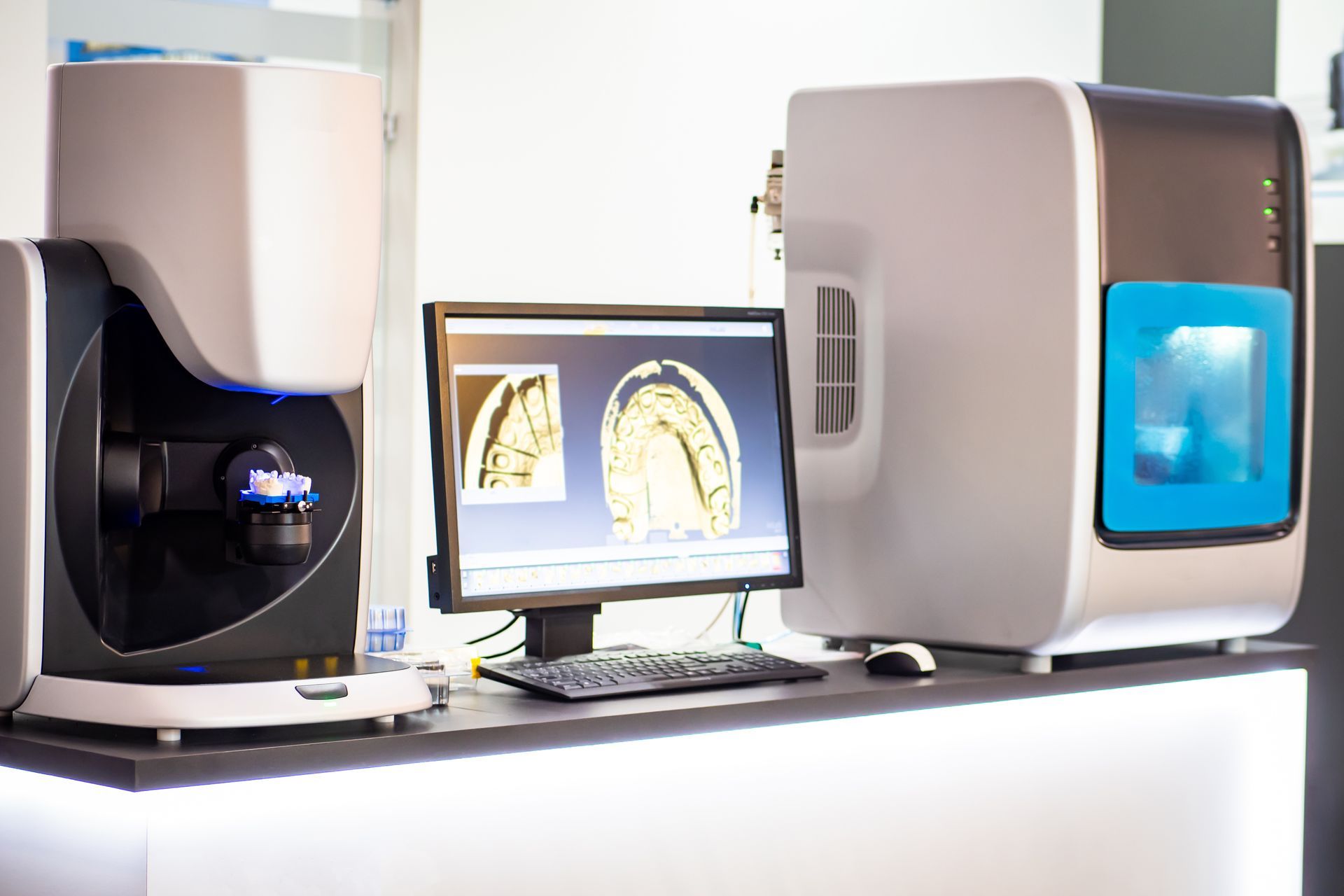

3D-printed dentures are crafted using advanced scanning technology to capture precise digital impressions.

This ensures an accurate fit and minimizes the need for adjustments. The materials used in 3D printing are durable and designed to mimic the look and feel of natural teeth, offering both functionality and aesthetics.

For patients, this means increased comfort and confidence. For dental practices, it means fewer remakes and better patient satisfaction. The precision of 3D printing reduces human error, making it a reliable option for both creating new dentures and repairing existing ones.

The Speed Advantage: Faster Repairs and Replacements

Time is a critical factor in denture repairs, especially for patients relying on their dentures for everyday activities. Traditional repair processes can take days or even weeks, requiring physical impressions, manual adjustments, and significant waiting times. This can be inconvenient and frustrating for patients.

With 3D printing, the repair timeline is drastically reduced. Here’s how it works:

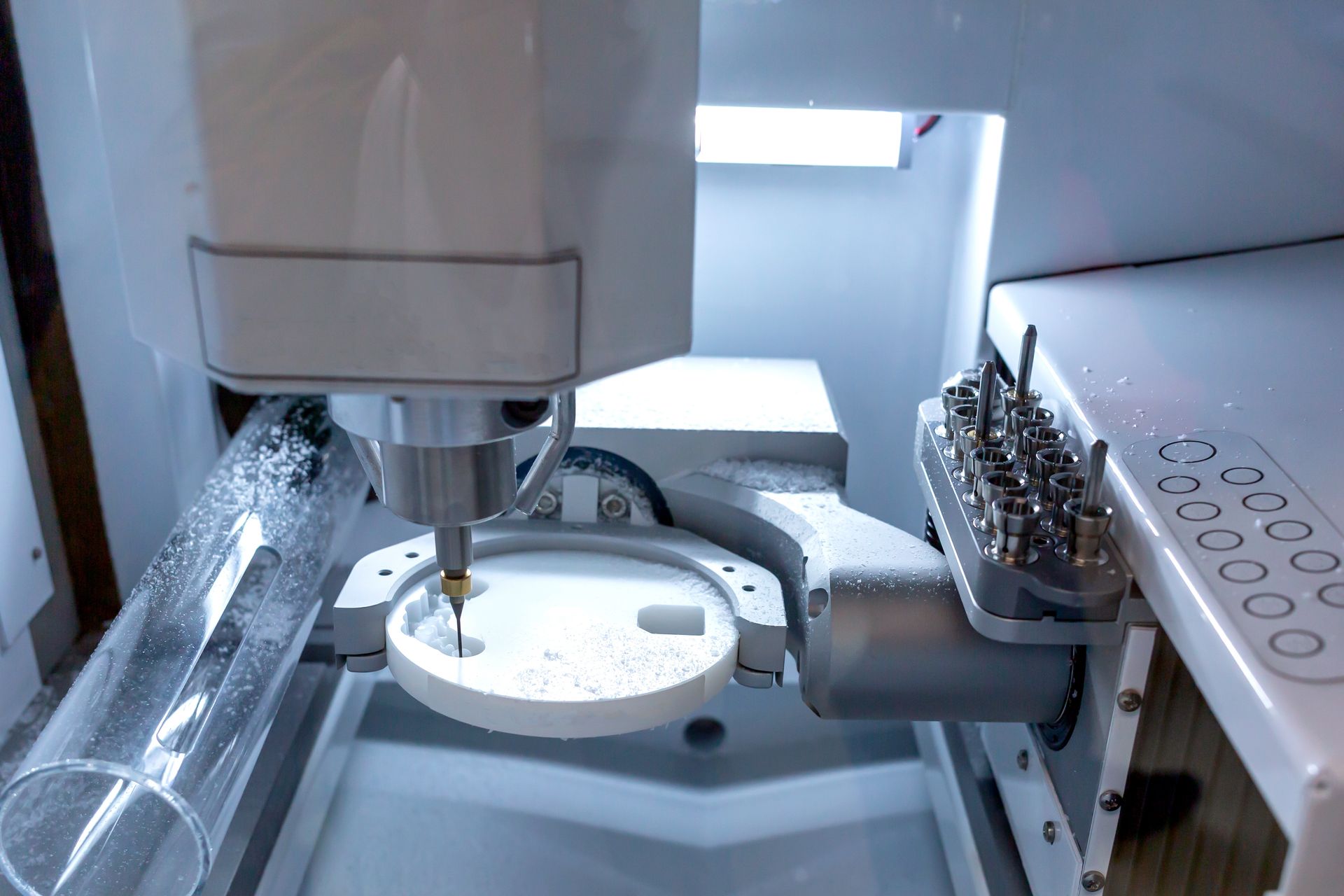

- Digital Scanning: Damaged dentures are scanned to create a precise digital model.

- CAD Software: The scanned data is used to design the repair or replacement digitally.

- 3D Printing: The updated denture is printed within hours using high-quality dental materials.

This streamlined process allows dental professionals to repair or replace dentures on the same day, in many cases. Patients no longer have to endure extended periods without their dentures, and practices can serve more patients efficiently.

Cost-Effective Solutions for Patients and Practices

One of the most significant advantages of 3D printing in dentistry is its cost-effectiveness. Traditional denture repairs and replacements involve multiple steps, including manual labor, shipping costs for impressions and models, and the use of expensive materials. These factors contribute to higher costs for both dental practices and patients.

3D printing eliminates many of these expenses by digitizing the process. Key cost-saving benefits include:

- Material Efficiency: 3D printing uses only the materials needed for the repair, reducing waste.

- Elimination of Shipping Costs: Digital files can be sent instantly, eliminating the need for physical shipping.

- Reduced Labor Costs: Automated processes minimize the need for manual intervention, saving time and money.

For patients, this translates to more affordable repairs and replacements without compromising quality. Dental practices can also allocate resources more effectively, enhancing profitability and patient care.

Superior Quality and Precision

The precision of 3D printing ensures that repairs and replacements are more accurate than ever before. Traditional methods often involve multiple adjustments to achieve the desired fit, which can be time-consuming and uncomfortable for patients. In contrast, 3D-printed dentures are designed with exact specifications, minimizing the need for follow-up visits.

Additionally, 3D printing allows for consistent quality in every repair. The digital workflow ensures that each step of the process is meticulously controlled, resulting in durable and well-fitting dentures. Patients can trust that their repaired dentures will feel natural and perform effectively.

Environmentally Friendly Practices

Beyond speed and cost savings, 3D printing contributes to environmentally sustainable dentistry. Traditional denture repairs generate waste from materials like alginate impressions and stone models. These materials often end up in landfills, contributing to environmental concerns.

3D printing significantly reduces waste by using digital files and only the necessary materials for each repair. Dental practices adopting this technology can reduce their environmental footprint while providing high-quality care to their patients. This aligns with the growing demand for eco-friendly practices in the healthcare industry.

How 3D Printing Enhances Patient Experience

For patients, the benefits of 3D printing extend beyond faster repairs and lower costs. The technology offers a more comfortable and convenient experience overall. Digital scanning eliminates the need for messy impressions, which many patients find unpleasant. The shorter turnaround times mean patients spend less time waiting and more time enjoying their restored smiles.

Moreover, the precision and durability of 3D-printed digital dentures give patients confidence in their appearance and functionality. Knowing that their digital dentures are crafted using cutting-edge technology provides peace of mind and enhances overall satisfaction.

A Bright Future for Dental Practices

The adoption of 3D printing is not just a trend—it is a strategic investment in the future of dentistry. Dental practices that incorporate 3D printing into their workflows can offer faster, more affordable, and higher-quality services to their patients. This positions them as leaders in the field, attracting new patients and retaining existing ones.

For practices partnering with advanced dental labs like Vitality Technologies, the transition to 3D-printed dentures is seamless. These labs provide the tools, expertise, and support needed to integrate this revolutionary technology into everyday operations.

Transforming Denture Repairs with 3D Printing

3D printing is transforming the way denture repairs and replacements are handled, offering unmatched speed, precision, and cost savings.

3D printed dentures bring clear benefits for both patients and dental practices: faster turnaround times, reduced expenses, and superior results. By embracing 3D printing technology, dental professionals can deliver an exceptional patient experience while streamlining their workflows.

Vitality Technologies is at the forefront of this revolution, empowering practices to stay ahead in the rapidly evolving world of digital dentistry.