The Important Role Soldering Plays in Dental Technology

Soldering plays a vital role in the manufacture and repair of dental technology. Soldering is a process that involves melting a filler metal into a joint between two pieces of metal to form a strong and durable bond. This process is used extensively in the dental industry for a variety of applications, from the manufacturing of dental devices to the repair of existing ones.

Why Dental Technicians Must Learn Dental Soldering

Dental soldering is an essential skill for any dental technician to learn. Firstly, dental soldering helps dental technicians to create precise connections between metal components. By mastering the skill, technicians can create connections that are much more precise than those made with alternative methods. This ensures that dental restorations are strong and secure, thus providing patients with results that are both aesthetically pleasing and durable.

Furthermore, dental soldering enables technicians to create connections between metal components that are smaller than those that can be made with other methods. This is especially important when creating complex restorations such as bridges, crowns, and dentures. By having the ability to create smaller connections, technicians can create restorations that are more precise and comfortable for the patient.

In addition, dental soldering helps technicians to create more durable connections between metal components. Unlike alternative methods, soldering creates connections that are much more resistant to wear and tear. This means the connections will remain strong and secure for longer, thus providing patients with long-lasting results.

Finally, dental soldering enables technicians to create connections between metal components more quickly than other methods. This makes the process of creating dental restorations more efficient and cost-effective for both the technician and the patient.

Important Requirements of Dental Soldering

For a soldered joint to be successful, several requirements must be met.

First, the two materials being joined must be compatible with each other. This means that the metals must have a similar melting point and that the metals should be able to bond together.

Afterward, the surfaces being joined must be properly cleaned and prepared. This will ensure that the joint is secure and that the metal components do not corrode or degrade over time.

Then, the soldering process must be performed correctly. This includes the use of an appropriate soldering tool and the proper application of the soldering material.

The most important requirement for a successful soldering process is the use of high-quality soldering material. This material must be able to withstand the high temperatures involved in the soldering process and the forces of the patient’s bite.

The material should also have a low melting point so that it can be easily manipulated and formed into the desired shape. Additionally, the material should not contain impurities or contaminants that could weaken the joint.

Final Thoughts

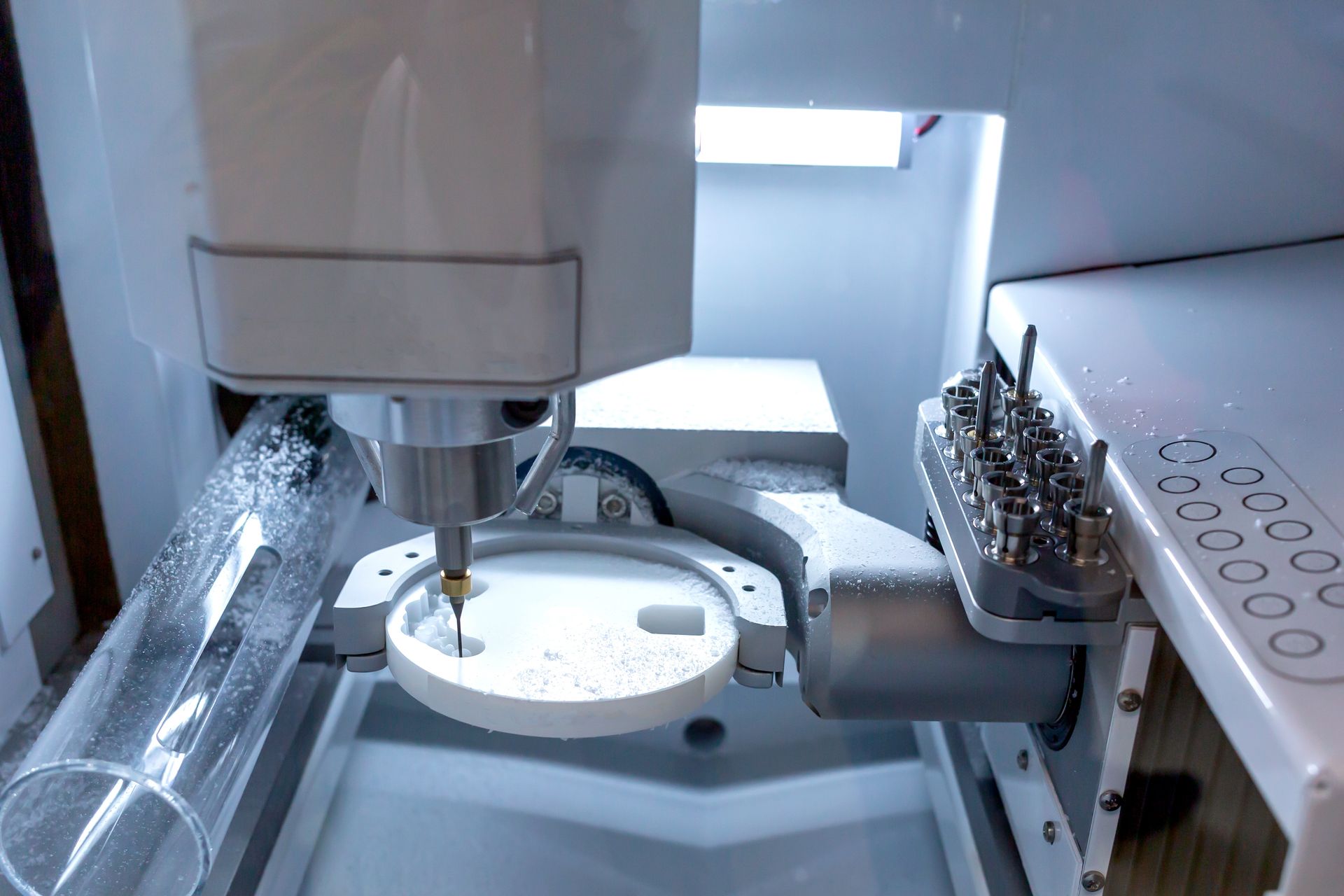

Soldering plays a vital role in dental technology. It is used to create dental prosthetics such as crowns, bridges, and implants. It is also used for repairs and to create orthodontic appliances.

Soldering is a skilled process that requires the operator to have a good understanding of the materials used and the techniques that are involved. The process is time-consuming and requires a lot of patience and attention to detail. Soldering is a critical component of dental technology, as it ensures that prosthetics and appliances meet the highest standards of quality and longevity.

Improve your

dental soldering with the help of Vitality Technologies. We are a digital dental laboratory that modernizes the entire dental lab process from start to finish. We have outfitted our laboratory with the most advanced technology and certified skilled technicians to consistently deliver the highest quality dental prosthetics. Get in touch with us today!