What You Need to Know About Digital Dentures

Dentures have long solved the problem of lost teeth. The technology used in these dental apparatuses has come a long way, too. While there are still those who prefer traditional dentures, a lot of dentists are now making the switch to digital dentures.

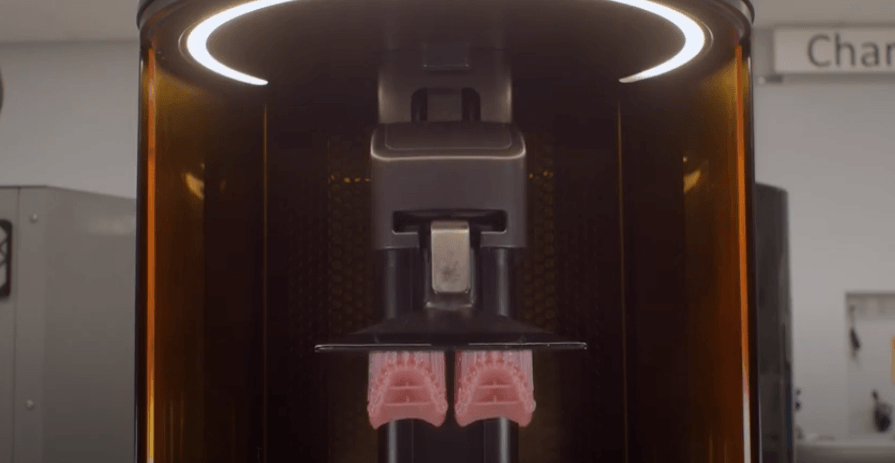

Digital dentistry simply pertains to describe the workflow or process used in the making of a CAD or CAM milled full denture, which is a relatively new system for denture manufacturing. Compared to traditional methods, digital dentures can offer a much better fit and improved comfort. Aside from that, this method also results in a more flexible denture that is preferred by more patients.

Curious about this latest denture innovation?

Learn More About Digital Dentures

How Digital Dentures Are Made

There are three factors that contribute to the making of digital dentures: advanced software, innovative dental devices, and high-quality materials.

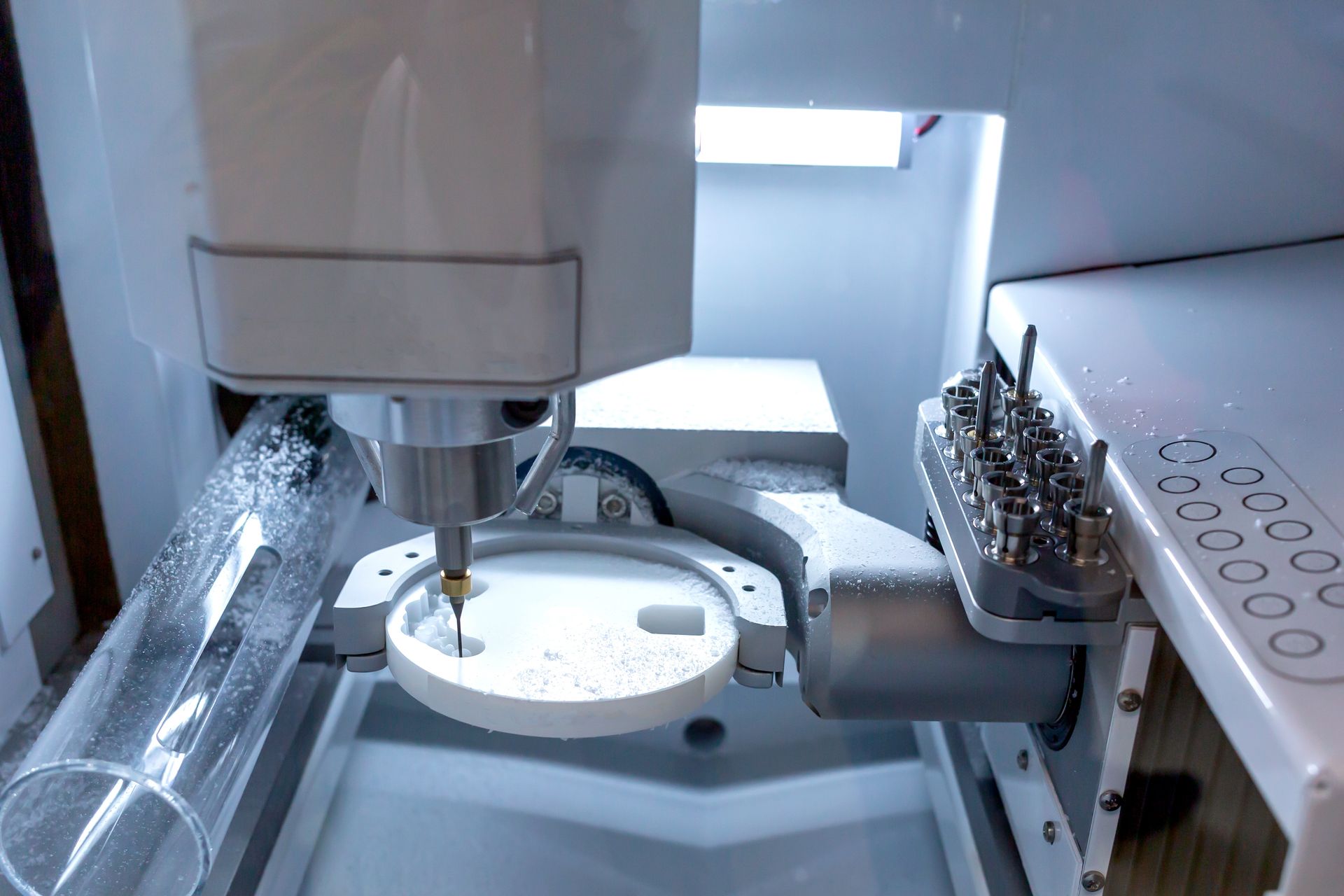

During the first appointment with the patient, the digital denture technique will accurately capture both the occlusal plane and the vertical dimension. The impression of the patient’s teeth and gums will then be scanned in the dental laboratory using a 3D scanner.

Some digital impression systems require your teeth to be lightly dusted with titanium dioxide powder so both arches and bite can be scanned in detail. There’s a digital impression technology that makes use of digital photographs, while the other one captures videos. Either way, the imaging is done by laser for precision and safety.

The laser beam will take a 3D image of the gum and teeth so there won’t be a need for that unpleasant mold material to be placed in the patient’s mouth to get impressions. The digital impression of prepared teeth can be produced in about two minutes, and the opposite arch can be done in a minute.

Once the data is complete, it will be then transferred to the design software, which will conceptualize accurate arch shape and occlusal plane. The size and shape of the tooth will also be based on the data collected. The dental technician will then fine-tune the try-in dentures.

If there are any modifications needed, they will be scanned and merged with the first one done to create the final dentures.

Why Choose Digital Dentures

Accurate Fit

The CAD/CAM technology lets dentists create dentures with more accuracy with less effort. The technology delivers a denture that fits better, eliminating the hassles of uncomfortable dentures that could be loose.

Durable Dentures

Digital dentures are made using high-quality acrylic that is subjected to extremely high pressure and temperature, which makes them very durable. Digital dentures are also made from a single unit of acrylic, meaning there is no bonding that could wear off over time.

Faster Processing

Patients will prefer options with a faster turnaround time. Traditional dentures can take up to a month, while digital dentures can be done in one to two weeks.

Faster Replacement

In case patients lose or break their dentures, they can be replaced in as early as two days because their digital scans are saved and just need to be transferred back to the software for production.

Cost-Effective Solution

Ultimately, digital dentures are more cost-effective. Not only do they require fewer visits, but there will be no frequent adjustments either.

Conclusion

It is obvious that the future of dentures is digital. It is amazing to see the strides that digital dentistry makes that help improve not only the way dentists work but also the experience of the patients who get treatments. Of course, dentists need to make sure that when choosing dental labs for dentures that they choose one that embraces innovations so they both can grow in the future.

If you want to learn more about the workflow involved in digital denture making, Vitality Technologies is here to answer your questions. Our full-service dental laboratory can provide your patients with digital dentures as well as fixed prosthetics, implants, and more. Contact us today to know more!