Our Guide to Prefabricated Teeth. What You Need to Know.

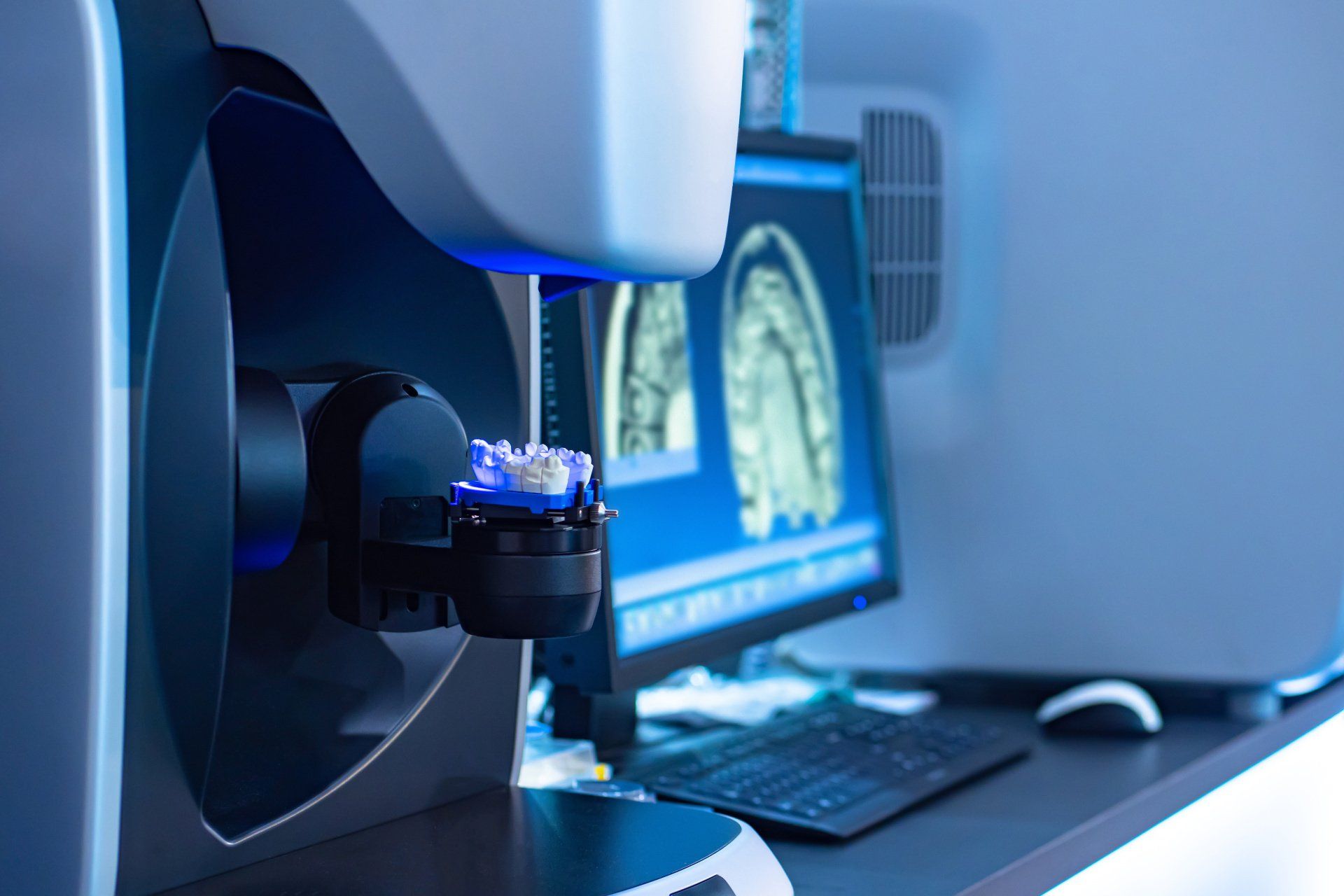

Dental technology has rapidly advanced to allow dentists to keep up with a high aesthetic level, creating the demand for top-quality prosthetic restoration through prefabricated or acrylic teeth. Dentists and patients alike expect prosthetic restoration to involve the use of modern materials, ensuring the results are long-lasting, durable, and resistant to abrasion.

While the prosthetic tooth has long been part of a dentist’s daily work, what has changed over the years is the standard of quality. To keep up with the demand, dentists have worked with

reliable dental laboratories to provide outstanding prefabricated teeth made of high-performing acrylics.

Here’s what you need to know about them:

Behind Acrylic Teeth

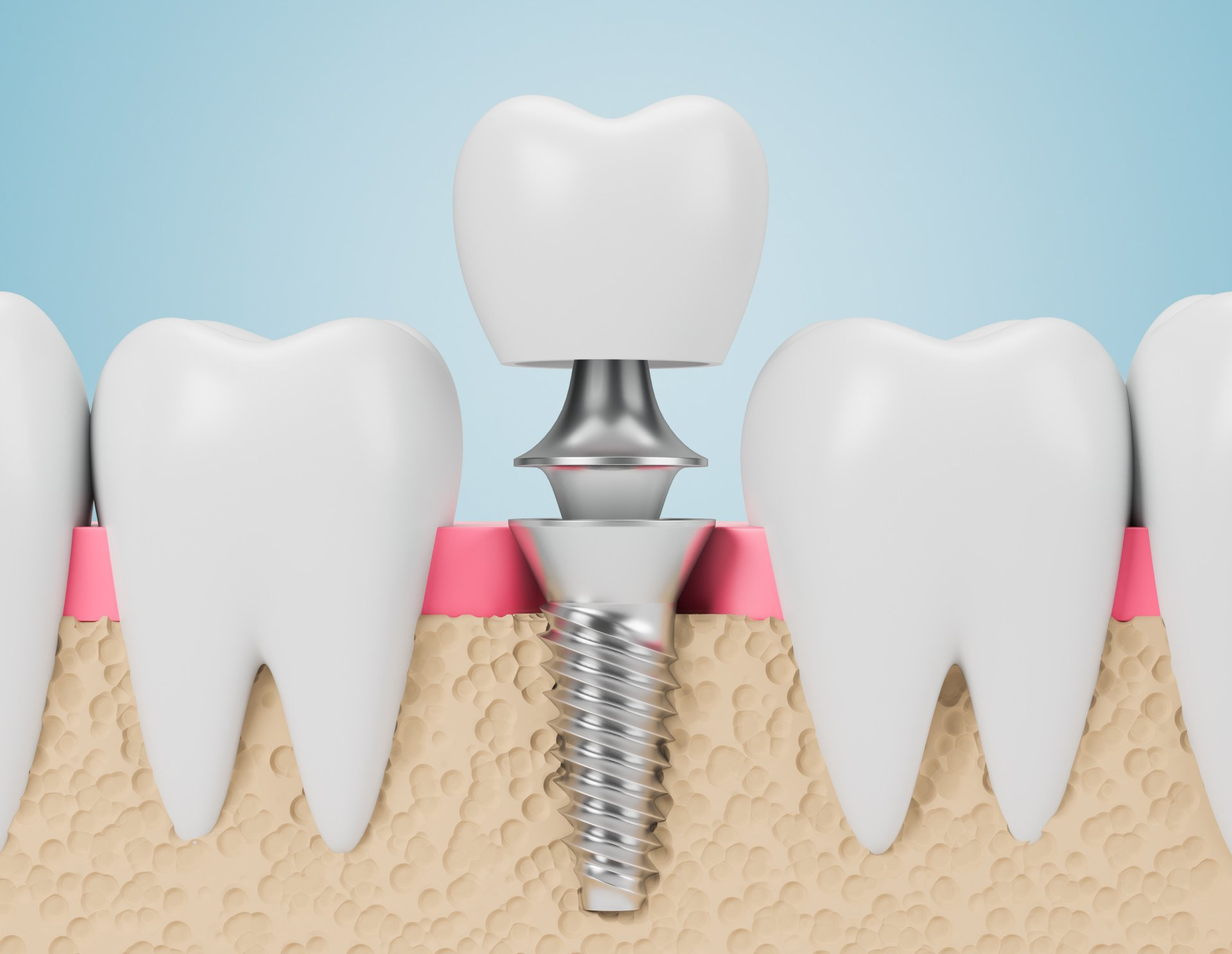

Dentists have steadily worked on prefabricated teeth to find ways to make them sturdier, stronger, and display outstanding esthetic qualities. Losing teeth is often a challenging experience for patients since it can cause discomfort all over the body. Making dental restorations on implants a more comfortable solution is a bigger priority than ever, as it offers more stable support in masticating and speaking. Providing more modern prosthetics often makes a world of difference in the long run to those who struggle with tooth loss, underlining their importance even more.

Dental patients today enjoy a more comprehensive range of choices than ever before. They can use full, removable dentures to reinforce their chewing and speaking abilities. They can also use flexible partial dentures if it suits their preferences better. Overall, new dental restorations must involve creating high-quality prefabricated teeth to continue improving the patient’s quality of life.

A prefabricated Tooth's Required Properties

The required properties for modern prosthetics are high, whether for partial or full dentures. Removable prosthetics that support implants need prefabricated teeth designed with additional abrasion resistance while being esthetically pleasing, resembling the rest of the patient’s natural teeth. For this reason, dental practices must work with dental labs that use prefabricated teeth from materials that offer longevity, high resistance to abrasion, and outstanding visuals, including the color and shape.

The material must fulfill various criteria, such as shade stability, plaque resistance, biological tolerance, high grinding strength, good polishing qualities, and many others. A particular material that fulfills these requirements is the double cross-linked acrylic, used for many different prefabricated tooth lines.

The Science Behind the Acrylic

The DCL acrylic is an altered polymethyl methacrylate variant or PMMA, where the polymer filler and matrix are adequately cross-linked. The DCL material boasts better compressive strength yet the same flexibility as that of traditional PMMA. This quality is due to the double cross-linking, removing the flaws of conventional PMMA teeth, like exposing non-cross-linked, soluble polymer beads during the grinding process.

The smartly formulated DCL acrylic material structure provides durability, longevity, stability, and the desired abrasion resistance. Due to DCL acrylic’s advantages, it increases dentures’ longevity and is less prone to discoloration, making it the ideal material for implant-supported removable dentures.

Conclusion

Prefabricated teeth have been crucial in restoring people’s ability to speak and chew while reducing other discomforts experienced due to tooth loss. However, simply manufacturing acrylic teeth isn’t enough. To provide patients with an improved quality of life, dentists must work with reliable dental labs to produce prefabricated teeth made with DCL acrylic, which resembles natural teeth and bears higher resistance to decay.

If you’re looking for

dental labs for dentures, be sure to let us know at Vitality Tech LLC! We are a full-service dental laboratory serving clients nationwide, specializing in dental implants, fixed prosthetics, and high-end removable dentures.

Contact us today to find out more about the dental restoration products we can offer you!